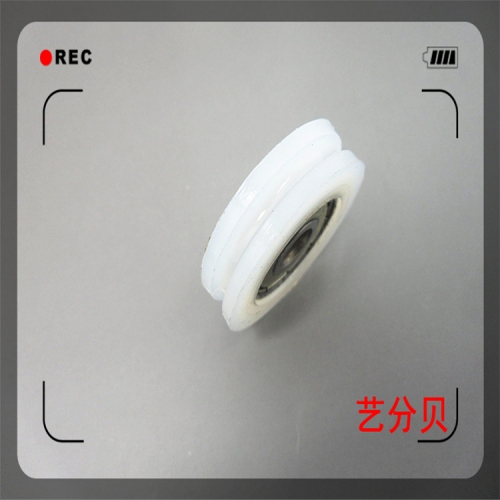

Silent anti rust bearing in shower room

When the free space of the bearing seat is Silent anti rust bearing large, the bearing speed is low, or under adverse environmental conditions, the grease needs to be used to prevent the invasion of dust, moisture, etc., the amount of re lubrication can be appropriately increased.

During the re lubrication operation, it shall be ensured that the supplemented new grease reaches the working surface of the bearing parts accurately. The old grease originally used shall be discharged in time. Theoretically, the amount of grease filled shall be discharged. However, considering the evaporation of the base oil, a little more grease can be added.

Oil lubrication

Oil lubrication is recommended in the following cases:

·Bearing under high temperature and high speed operating conditions

·Occasions where bearing friction heat or other heat needs to be dissipated

·When the grease lubrication cannot meet the requirements

·When oil lubrication is used on adjacent mechanical Silent anti rust bearing devices